Metal Stamping Versus Precision Sheet Metal Fabrication

Metal stamping and precision sheet metal fabrication are processes used to manufacture metal parts. While both processes have pros and cons, you must choose the most practical and efficient one for your project. Accordingly, let’s analyze metal stamping and precision sheet metal fabrication to determine which technique will best align with your design and production requirement needs.

Precision Metal Stamping

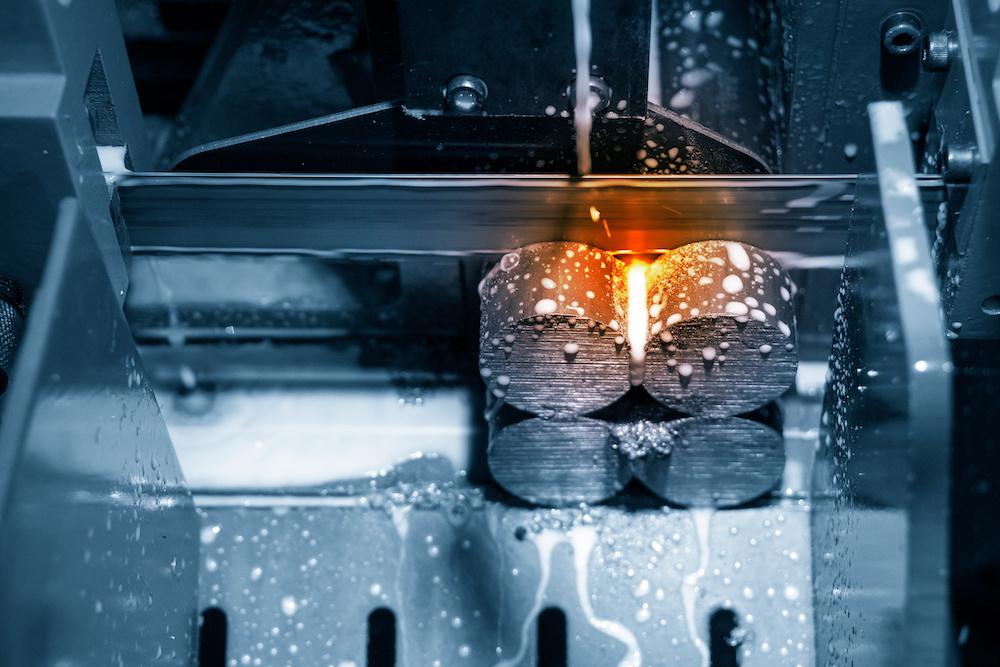

What is metal stamping?

Metal stamping (or pressing) is comprised of multiple manufacturing processes that include, but are not limited to, blanking, bending, flanging, punching, and coining. This process can be completed in a single-stage operation or through several operations by placing a flat sheet of metal, in either coil or blank form, on a stamping press to shape it to its desired state.

Metal stamping pros

- An ideal long-term, and cost-effective, option for mid-to-high volume production

- A precipitously higher throughput solution for producing large quantities and volumes of complex and precise parts than sheet metal fabrication

- Can be a highly automated process that helps reduce labor costs input and repeatedly produces tight tolerances

- High levels of reliability, repeatability, and reproducibility for high-volume parts and pieces

- Help reduce per-unit costs

- Reduced scrap rate

- Reduced labor costs

Metal stamping cons

- High upfront tooling costs

- The time required to develop tooling often causes longer pre-production times

- Can be costly to implement design changes after tooling is produced

- Short-run production has higher piece price costs due to longer setup times

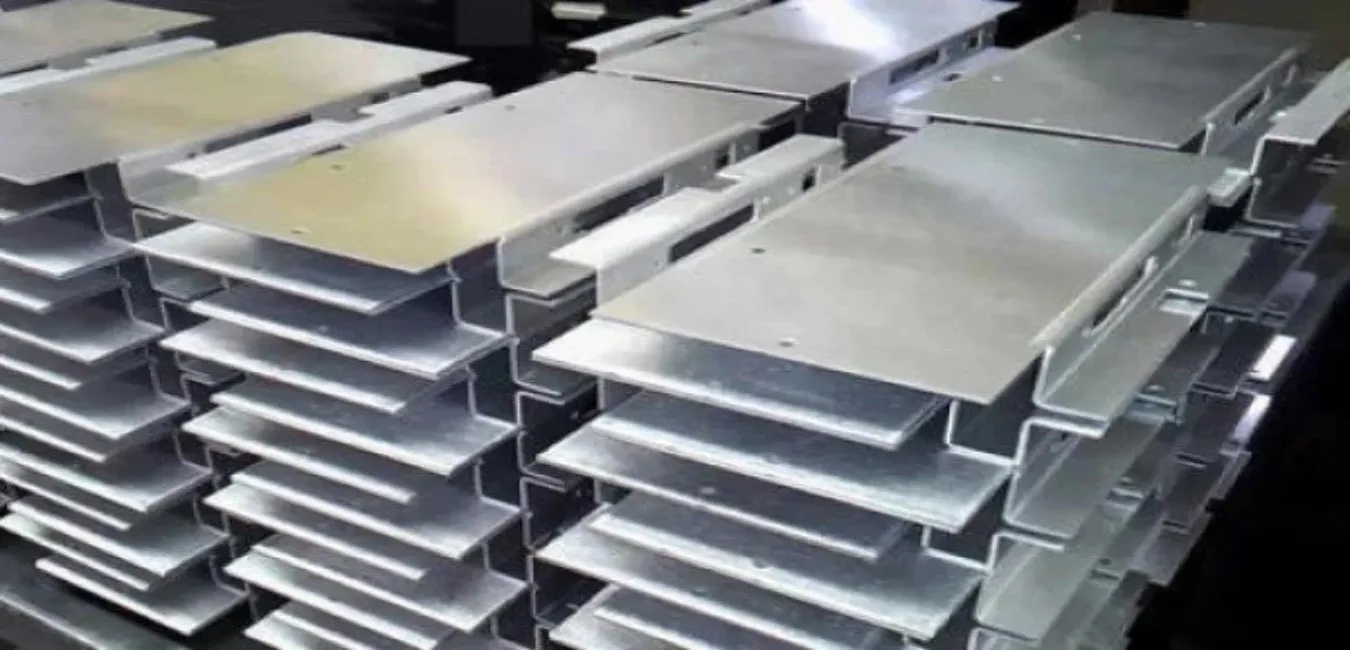

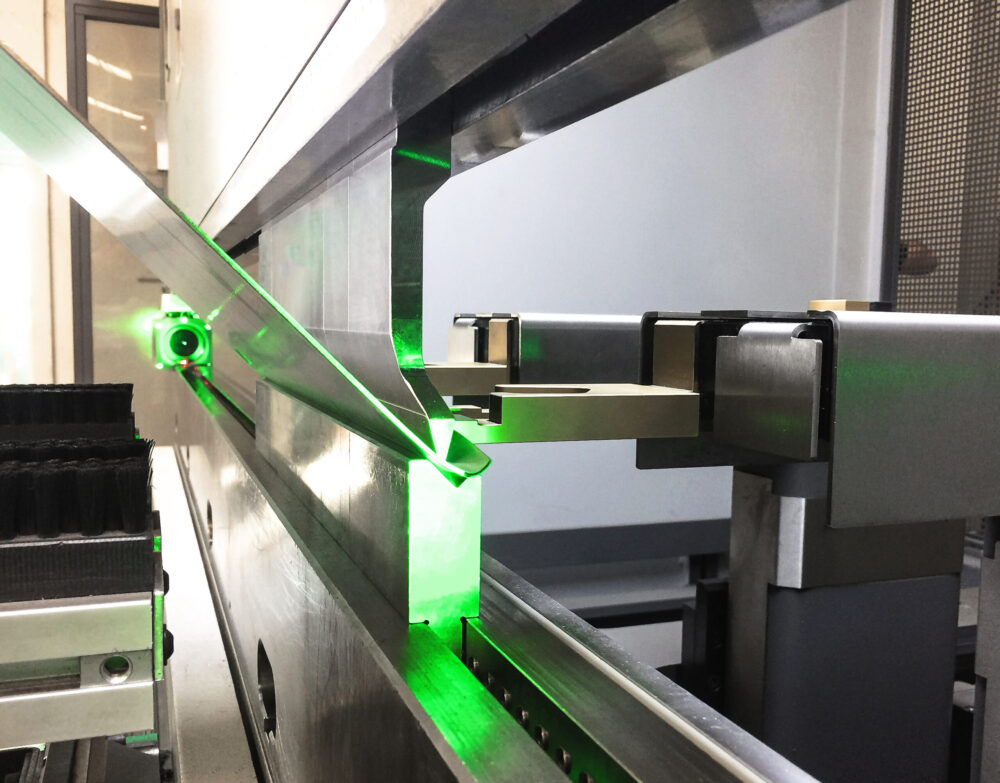

What is precision sheet metal fabrication?

Precision sheet metal, which consists of a series of processes like punching, laser cutting, welding, bending, forming, hardware insertion, and assembly, is a valuable metalworking method that is employed to transform flat sheets of common steel, stainless steel aluminum, and many more alloys into virtually any shape. This robust process is used to produce a diverse range of parts and products and is especially useful when creating functional parts, such as panels, brackets, and enclosures.

Precision sheet metal fabrication pros

- Effective for creating complex products with mass customization

- Shortened initial startup time

- Easy to implement design changes and make adjustments

- Greater flexibility and versatility

- Extremely economical for short production runs

- Produces rapid, and far easier, prototyping

Precision sheet metal fabrication cons

- Higher labor costs and more labor-intensive

- Deep-drawn shapes not feasible

- Requires a longer production period

- Slower production process

- Material waste can be higher because costs are generally more expensive

What process should you use?

Metal stamping and precision sheet metal fabrication are both common, and effective, metal formation methods. However, depending on a specific project’s circumstances, one process will prove to be more advantageous to create your product or part. With that noted, metal stamping is the more economical method as your product volume increases and order quantities grow. Ultimately, by reducing lead times and improving quality, metal stamping can help you minimize costs and maximize profits.

Get The Help You Need

Independence Machinery specializes in machine repair and sales, and we’re dedicated to providing you with top-notch solutions. Contact us now to explore how we can assist you.

Contact us for recommendations on keeping your machinery safe, updated, and functioning to the highest level of safety and certified standards.