Optimizing Bandsaw Blade Performance: Maintenance Tips

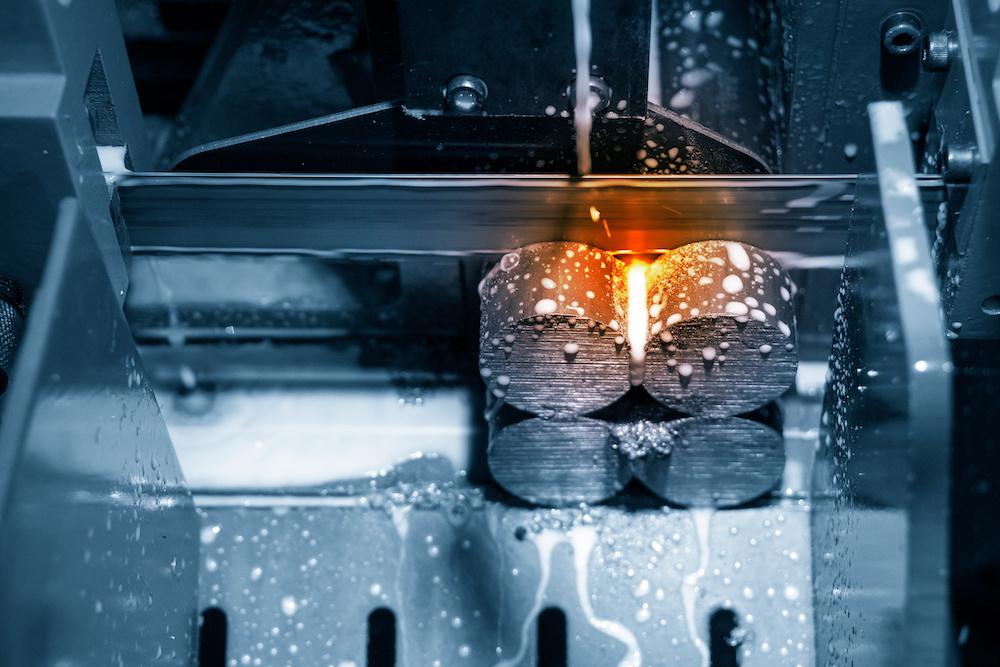

There are various reasons why a Bandsaw Blade might fail, ranging from improper usage to wear factors that lead to premature failure during sawing operations. While some failures are preventable, technical issues like wear factors can’t always be avoided entirely. However, taking proactive measures can minimize the causes of failure. Operator training is crucial in understanding the reasons for technical failures and setting proper parameters for different applications, ultimately impacting the Bandsaw Blade’s lifespan.

Independence Machinery offers replacement Bandsaw Blades and repairs tailored to your metalworking needs, learn more about our service here.

Avoiding Bandsaw Blade Failure

Maximizing uptime and productivity requires ensuring that your saw blade functions correctly. While several common causes contribute to blade failure, it’s essential to distinguish between normal wear and severe premature wear. Unusually rapid wear can be influenced by factors such as material designation, strength, microstructure, and dimensions. Material hardness directly correlates with higher cutting temperatures and consequent premature wear.

COMMON CAUSES OF BLADE FAILURE

- Blade speed exceeds material capabilities, leading to excessive heat and rapid wear.

- Inadequate feed rate results in teeth rubbing against the material instead of cutting.

- Cutting hardened or abrasive materials (e.g., fiberglass) accelerates wear.

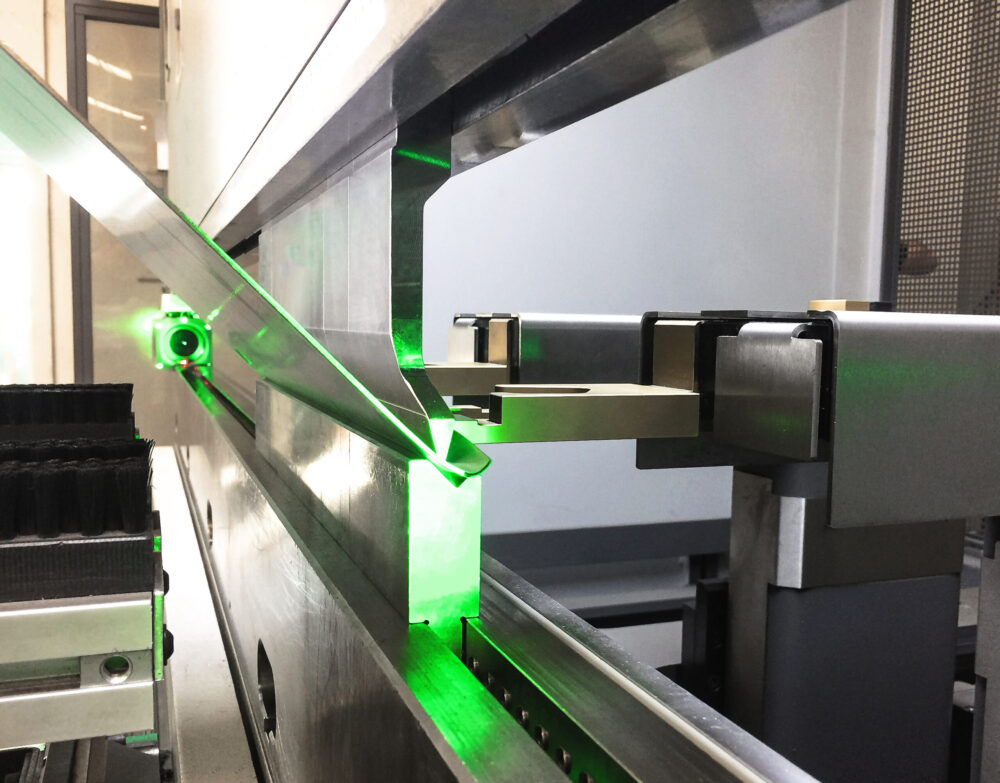

- Excessive blade tension or overly tight guides can harden the blade and cause cracks.

- Ineffective chip brush fails to clean teeth properly.

- High band speed generates excessive heat.

- Improper tooth pitch leads to inadequate chip clearance.

- Excessive feed pressure produces oversized chips, exceeding gullet capacity.

- Coolant issues impact cutting performance.

- Improper material positioning or clamping, or material movement during cutting.

SAW BLADE REPLACEMENTS

Whether you’re experiencing chipped teeth or subpar performance during sawing operations, a new Bandsaw Blade can enhance performance. Our Service Engineers are on hand to address any queries and ensure you find the ideal Replacement Blade. With a vast inventory of Replacement Bandsaw Blades and knowledgeable staff, we guarantee the perfect replacement.

Our Service department is fully equipped to handle various metal-cutting saws. Contact us today, and our Service Engineers will assist you in finding the perfect Replacement Saw Blade.

Reach out to us today and discover your Replacement Bandsaw Blade with Independence Machinery!

Get The Help You Need

Independence Machinery specializes in machine repair and sales, and we’re dedicated to providing you with top-notch solutions. Contact us now to explore how we can assist you.

Contact us for recommendations on keeping your machinery safe, updated, and functioning to the highest level of safety and certified standards.