Maintaining Safety Standards in Industrial Machinery in the Aerospace Industry

Discover the importance of safety standards in aerospace industrial machinery and how it contributes to minimizing risks, injuries, and operational loss. From maintenance to personnel training and advanced safety technologies, uncover the measures that ensure day-to-day safe operation in the aerospace industry.

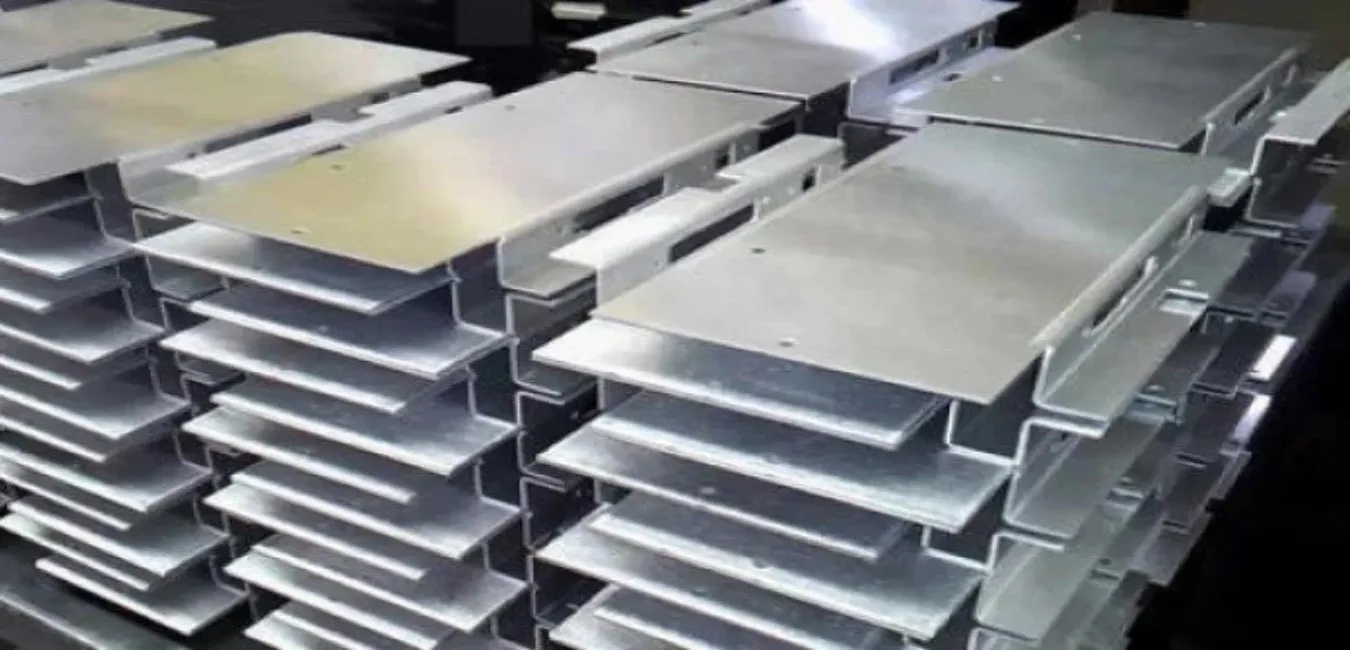

The aerospace industry relies heavily on advanced industrial machinery for the manufacture, assembly and testing of critical components of spacecraft and aircraft. With this comes a heightened need for safety standards to ensure that machinery is operated, maintained, and serviced correctly to eliminate risks in the production process, prevent injuries, and minimize material loss. Here’s an overview of safety standards in industrial machinery within the aerospace industry.

Strict Maintenance and Inspection Protocols

Maintaining safety standards in industrial machinery requires dedication to machine “health” via regular and thorough inspections, followed by knowledge of best practices regarding machinery operation and maintenance. In aerospace, machinery undergoes stringent preventive maintenance checks from the component level up to the entire system, ensuring that they run safely and optimally before deployment. This maintenance includes monitoring wear and tear, leak testing, and regularly scheduled inspections in line with industry regulations.

Training and Certification of Personnel

Maintenance technicians, operators and craftspersons working with machinery in the aerospace industry need to have requisite expertise, training, and certification in machine-specific safety measures. This guarantees operational awareness, optimal use, and compliance with safety standards that contribute to reducing hazards to a minimum. All personnel need to follow standard operating procedures for each machine to ensure that safety standards are followed at all times.

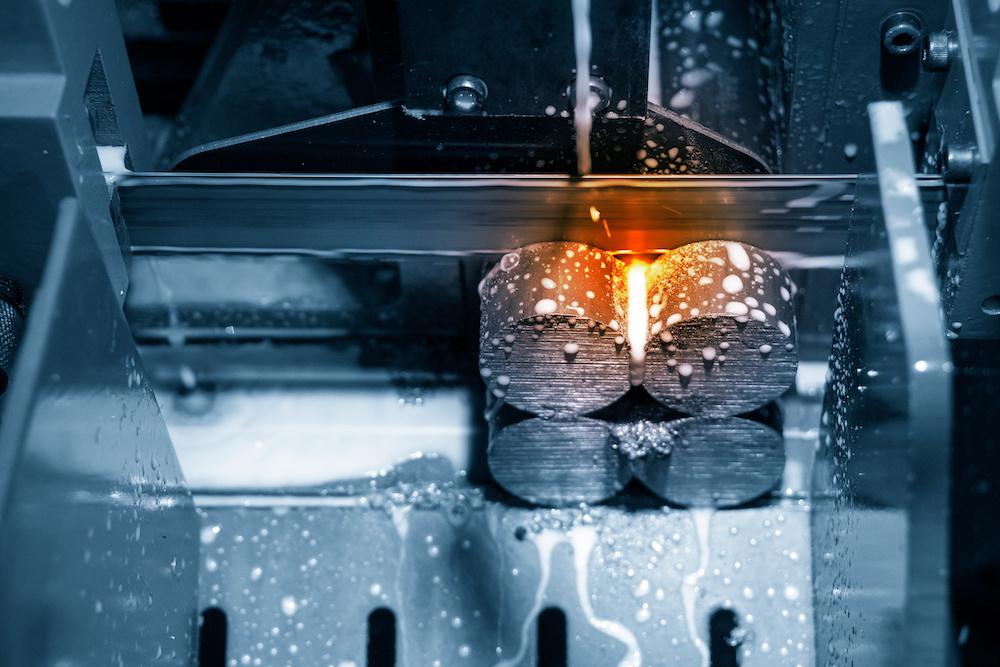

Use of Advanced Safety Technologies

Safety in industrial machinery is supported by innovative measures and applications. Machines have limit sensors, heat detectors, magnetic locks, safety gates among others, as standard come-ons that protect the technician or operator from potentially hazardous situations if machine failure occurs. These safety measures ensure early detection of issues, warning of malfunctioning before it gets out of hand.

Conclusion

Maintaining safety standards in the industrial machinery is a critical line of defense to prevent damage to both machinery and personnel. At Independence Machinery, we pride ourselves on providing top-of-the-line industrial machinery inspection, repair, and safety services to boost safe operation of machinery and compliance with regulations and standards.

Contact us for recommendations on keeping your machinery safe, updated, and functioning to the highest level of safety and certified standards.