As the year ends, it’s crucial to review your machinery’s maintenance plan. Independence Machinery can help you develop and implement a scheduled maintenance plan to prevent downtime, extend equipment lifespan, and improve efficiency.

Year-End Review: The Importance of Scheduled Maintenance Plans

As the year draws to a close, it’s an opportune moment for businesses to reflect on their machinery’s performance and plan for the future. At Independence Machinery, we emphasize the crucial role of scheduled maintenance plans in ensuring the longevity and efficiency of industrial machinery. A well-structured maintenance plan not only helps avoid unexpected breakdowns but also enhances overall productivity and operational efficiency.

Why Scheduled Maintenance Matters

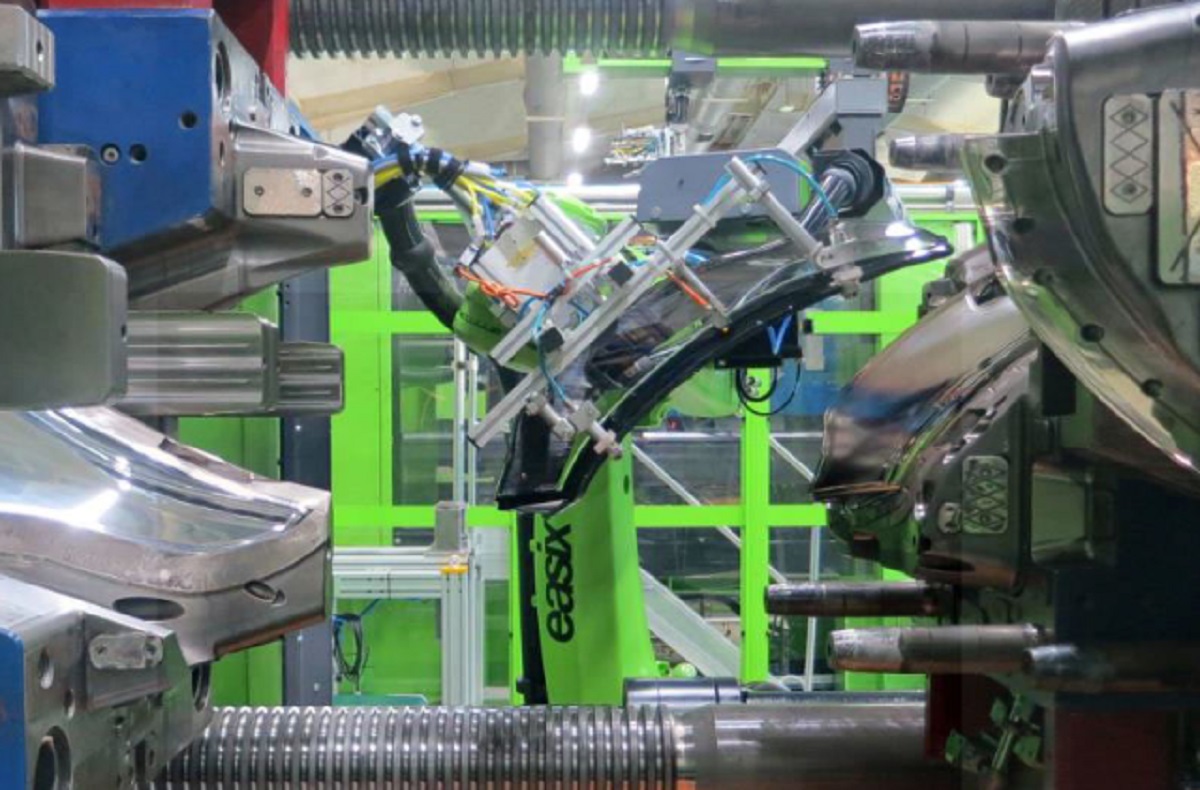

Scheduled maintenance is more than just a routine task; it’s a strategic approach to keeping your machinery in optimal condition. For industries relying on large industrial machinery, such as aerospace, defense, and automotive, the importance of regular maintenance cannot be overstated.

Here’s why scheduled maintenance is essential:

Prevents Unexpected Downtime:

- Early Problem Detection: Regular inspections and maintenance allow for the early detection of potential issues. This proactive approach helps prevent unexpected machinery failures that can lead to costly downtime and operational disruptions.

Extends Machinery Lifespan:

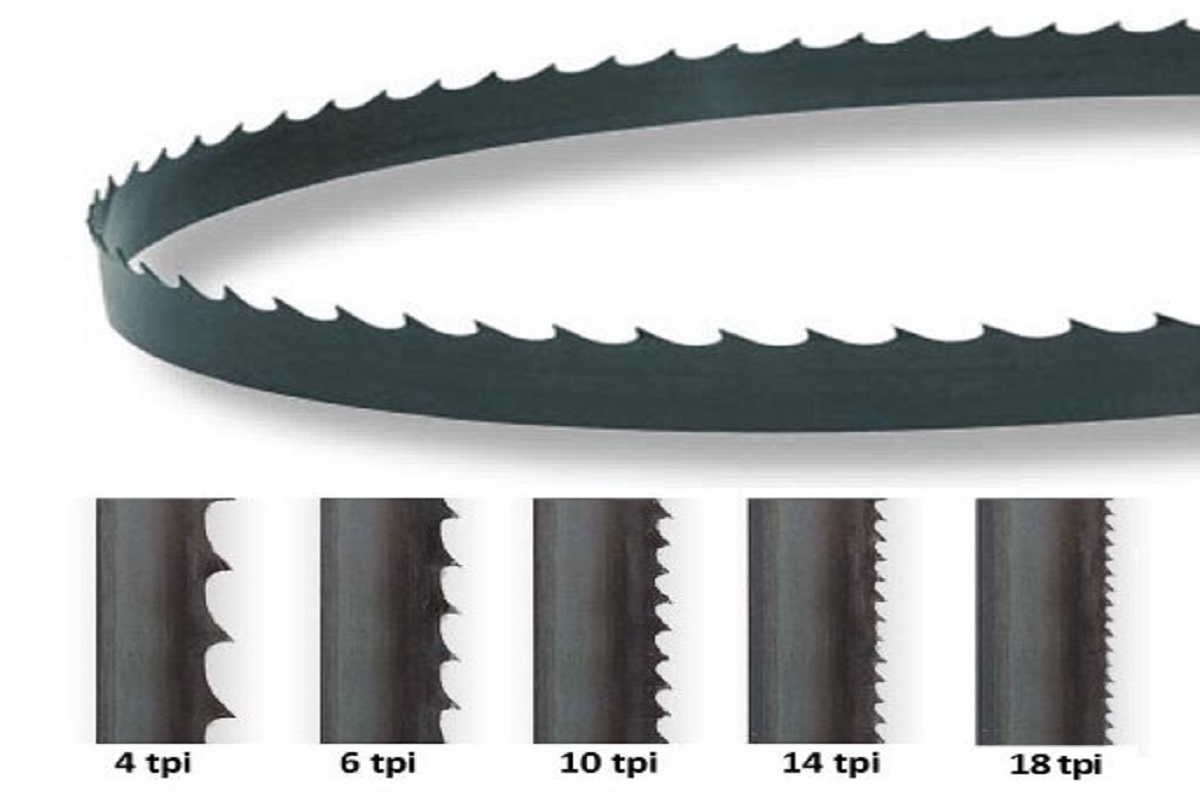

- Routine Care: Consistent maintenance ensures that all components of your machinery, including press brakes and other critical parts, are functioning correctly. This care extends the lifespan of both new and used machinery, protecting your investment over time.

Improves Efficiency:

- Optimized Performance: Well-maintained machinery operates more efficiently, resulting in better performance and reduced energy consumption. This efficiency not only lowers operating costs but also supports environmental sustainability goals.

Reduces Repair Costs:

- Cost Savings: By addressing minor issues before they become major problems, scheduled maintenance helps reduce the need for expensive repairs and replacements. This proactive approach minimizes long-term costs and ensures smooth operations.

Compliance and Safety:

- Regulatory Compliance: Regular maintenance helps ensure that your machinery meets safety and regulatory standards, reducing the risk of accidents and compliance issues.

Key Elements of a Scheduled Maintenance Plan

To maximize the benefits of scheduled maintenance, consider incorporating the following elements:

Regular Inspections:

- Conduct thorough inspections at scheduled intervals to identify any wear and tear or potential issues.

Preventive Maintenance:

- Implement preventive measures, such as lubrication, cleaning, and calibration, to keep your machinery in top condition.

Detailed Record-Keeping:

- Maintain detailed records of all maintenance activities, repairs, and inspections. This documentation is valuable for tracking the health of your machinery and planning future maintenance.

Tailored Maintenance Schedule:

- Develop a maintenance schedule tailored to the specific needs of your machinery and industry requirements.

Expert Support:

- Partner with experienced professionals like those at Independence Machinery to ensure that your maintenance plan is effective and comprehensive.

Independence Machinery’s Commitment to Your Success

At Independence Machinery, we offer a range of industrial machinery services, including diagnostics, repair, and maintenance. Our team is dedicated to helping you implement an effective scheduled maintenance plan that ensures the longevity and efficiency of your machinery.

For assistance with creating or optimizing your maintenance plan, or for any other machinery service needs, contact Independence Machinery today.

Connect With Us

Ensure your machinery operates at peak performance with a scheduled maintenance plan from Independence Machinery. Contact us to learn more about our services and how we can help.

Explore our website, give us a call at (877) 8-INMACH, Independence Machinery offers expert diagnostics, repairs, and maintenance to help you stay ahead. Contact us to learn more about how we can support your machinery needs.