Learn essential tips for hydraulic shear maintenance to maximize efficiency. Contact Independence Machinery for expert repair and maintenance services.

Essential Tips for Hydraulic Shear Maintenance

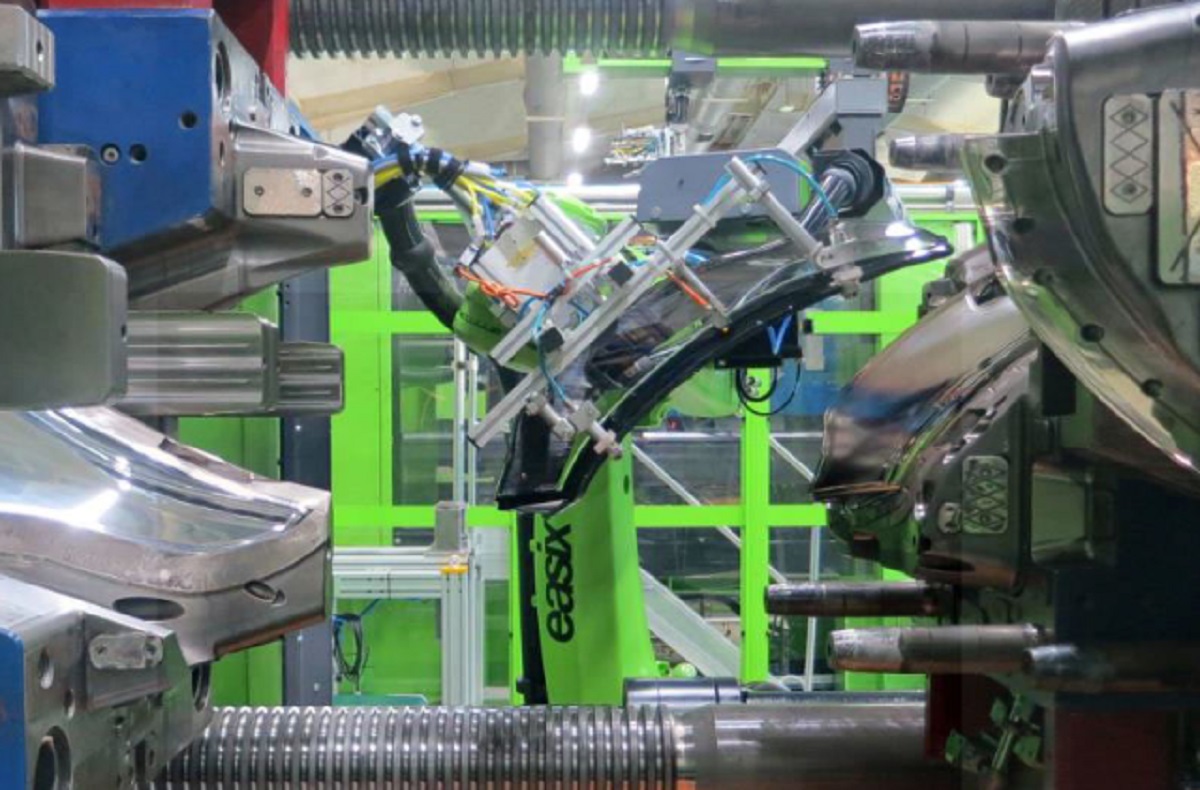

Hydraulic shears are a cornerstone in many industrial operations, offering precision and power for cutting various materials. To ensure these machines perform at their best, regular maintenance is crucial. Independence Machinery, with its extensive expertise in diagnostics, repair, maintenance, and training, shares essential maintenance tips to help you maximize the efficiency of your hydraulic shears.

1. Regular Inspection

Routine inspections are the first step in maintaining hydraulic shears. Check for any signs of wear and tear, including hydraulic leaks, blade condition, and any unusual noises during operation. Early detection of issues can prevent more significant problems and costly repairs down the line.

2. Blade Maintenance

The blades are the most critical component of hydraulic shears. Regularly inspect the blades for sharpness and any damage. Dull or damaged blades can lead to poor cutting quality and increased strain on the machine. Schedule blade sharpening or replacement as needed to ensure optimal performance.

3. Lubrication

Proper lubrication of moving parts is essential to reduce friction and wear. Follow the manufacturer’s recommendations for lubrication schedules and types of lubricants. Regular lubrication helps in maintaining smooth operation and extending the lifespan of your machine.

4. Hydraulic Fluid Check

Hydraulic fluid is the lifeblood of your shears. Regularly check fluid levels and quality. Low or contaminated hydraulic fluid can lead to decreased performance and potential damage to the hydraulic system. Replace hydraulic fluid according to the manufacturer’s guidelines.

5. Alignment and Calibration

Ensure that all components of the hydraulic shears are correctly aligned and calibrated. Misalignment can cause uneven cuts and increased wear on parts. Regular calibration ensures that your machine operates at peak efficiency.

6. Cleanliness

Keep your hydraulic shears clean and free from debris. Dust, dirt, and metal shavings can cause damage to the machine’s moving parts and affect its performance. Regular cleaning of the machine and its surrounding area can prevent these issues.

7. Professional Maintenance

While regular in-house maintenance is essential, professional servicing is equally important. Schedule periodic maintenance checks with experts who can perform thorough inspections, identify potential issues, and carry out necessary repairs.

Connect With Us

For professional maintenance and repair services, contact Independence Machinery. Our experts ensure your hydraulic shears operate at peak efficiency, reducing downtime and extending machine life.

Explore our website, give us a call at (877) 8-INMACH, or click the button below to find out more about how Independence Machinery can support your metal fabrication needs.