Discover how advancements in plate rolling technology are shaping the future of the industrial sector. Learn about the impact and prepare with Independence Machinery’s expert services.

Plate rolling technology has long been a cornerstone of the industrial sector, offering vital capabilities for shaping metal plates into complex forms used in a range of applications. As advancements continue to emerge, the future of plate rolling technology is set to revolutionize the industry, driving efficiency, precision, and innovation.

Advancements in Plate Rolling Technology

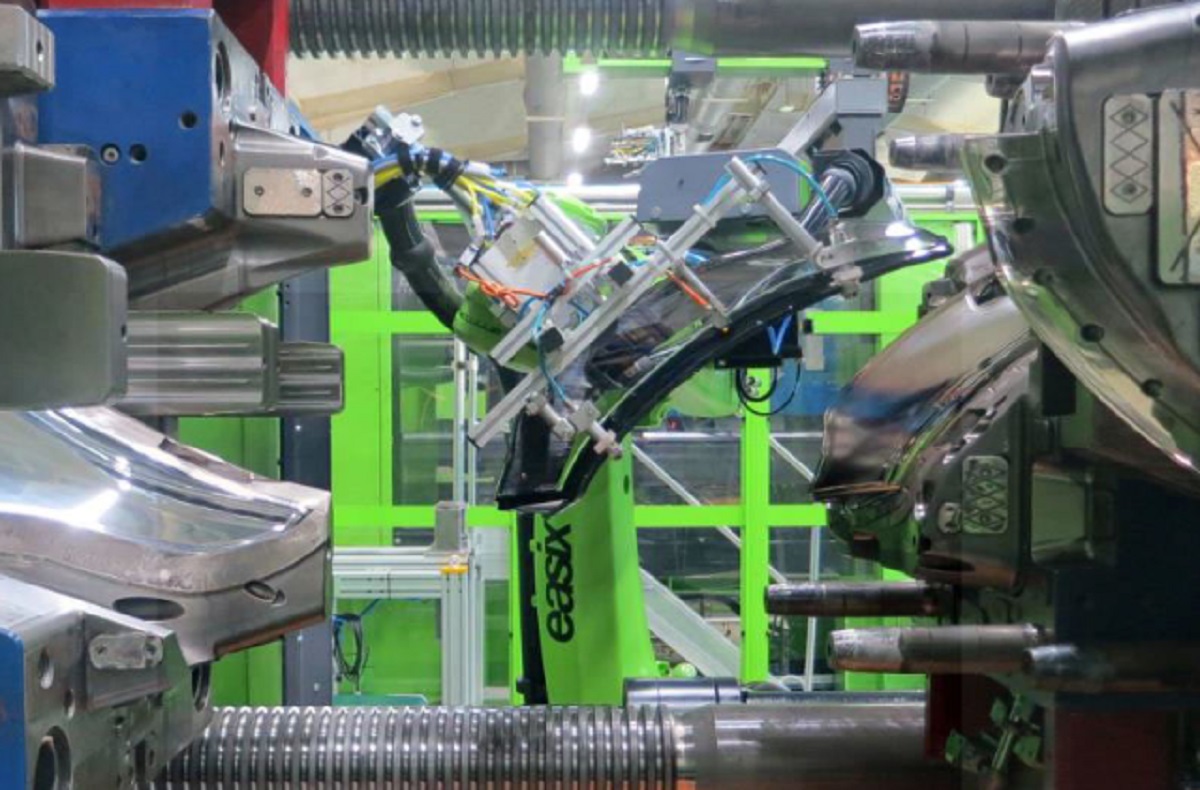

Modern plate rolling technology has seen significant advancements, including improved automation, enhanced precision, and increased energy efficiency. These innovations are transforming how industrial machinery operates, making it possible to produce more complex shapes with greater accuracy and less waste. Key developments include:

Advanced Control Systems: New control systems offer greater precision and automation in plate rolling, reducing human error and increasing production rates.

Enhanced Materials and Components: The use of advanced materials in plate rolling machinery improves durability and performance, allowing machines to handle more challenging tasks.

Energy Efficiency: Modern plate rolling machines are designed to be more energy-efficient, reducing operational costs and environmental impact.

The Impact on the Industrial Sector

The evolution of plate rolling technology is reshaping various industries, including aerospace, defense, and automotive sectors. These advancements enable companies to:

- Increase Production Efficiency: With faster and more accurate plate rolling processes, companies can meet demanding production schedules and reduce lead times.

- Improve Product Quality: Enhanced precision leads to higher-quality finished products, reducing the need for rework and minimizing material waste.

- Adopt Sustainable Practices: Energy-efficient machines and optimized processes contribute to more sustainable manufacturing practices.

Preparing for Future Innovations

As the industrial sector continues to embrace these technological advancements, it’s crucial to stay ahead of the curve with regular maintenance and updates to your machinery. Independence Machinery is committed to supporting you through these transitions by offering:

- Diagnostics and Repair: Expert diagnostics to ensure your plate rolling machinery operates at its best.

- Maintenance Services: Regular maintenance to prevent issues and extend the lifespan of your equipment.

- Training Programs: Training to help your team adapt to new technologies and maintain optimal performance.

Connect With Us

Stay Ahead with Cutting-Edge Plate Rolling Technology

Explore our website, give us a call at (877) 8-INMACH, Independence Machinery offers expert diagnostics, repairs, and maintenance to help you stay ahead. Contact us to learn more about how we can support your machinery needs.