Winter is coming—make sure your hydraulic shears are ready! Independence Machinery offers expert maintenance services to prepare your equipment for colder temperatures.

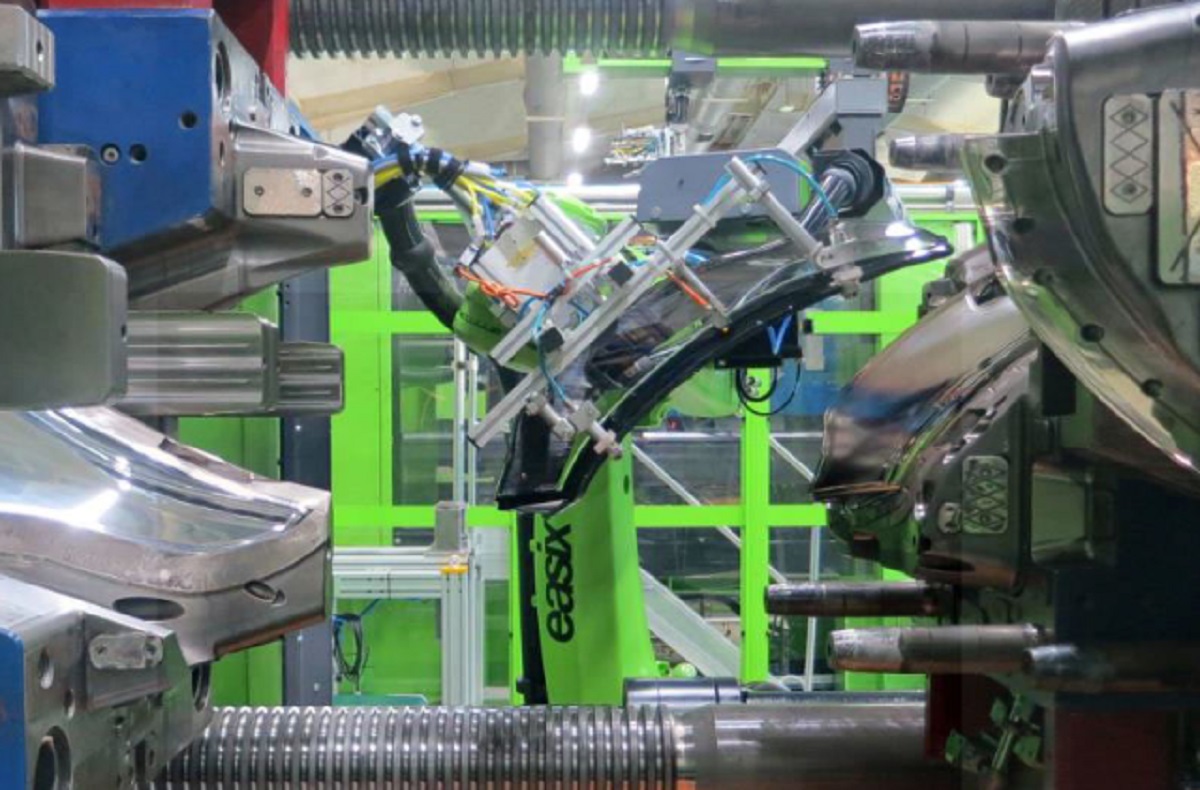

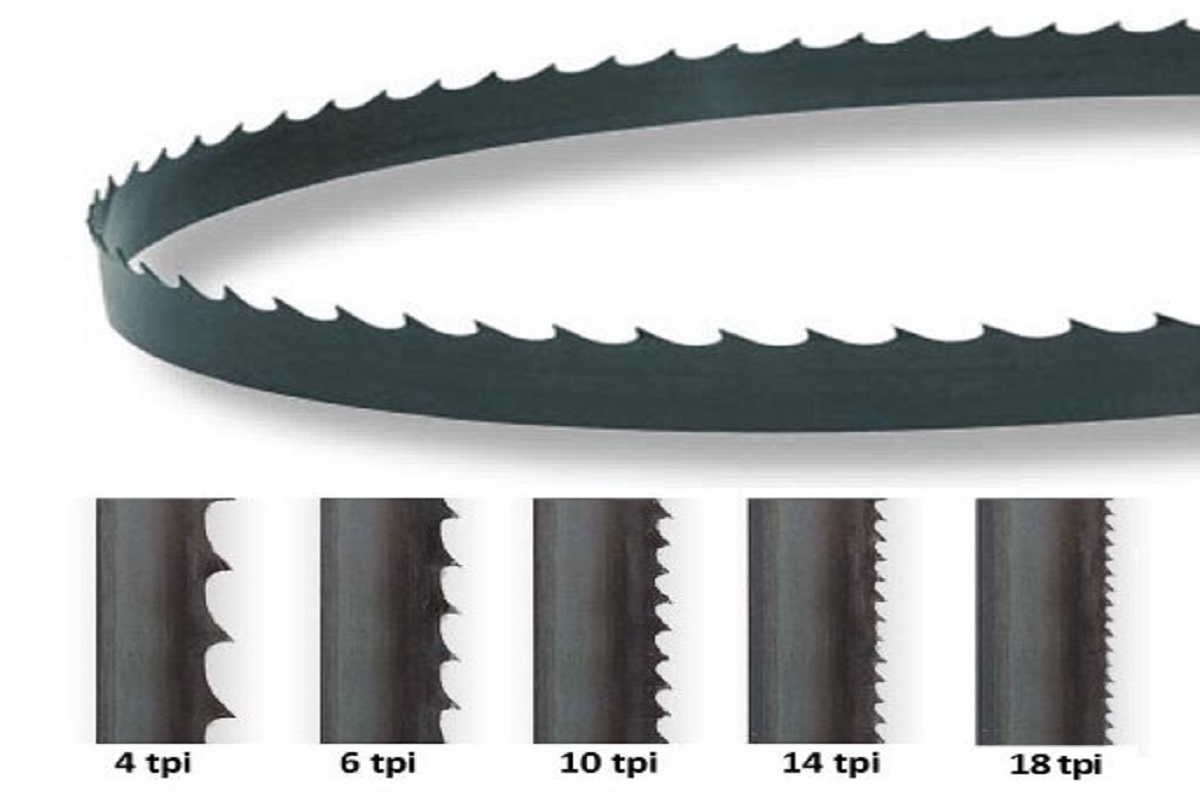

Preparing Your Hydraulic Shears for Winter: Essential Maintenance Tips. As winter approaches, it’s crucial to prepare your hydraulic shears for the colder months to ensure optimal performance and prevent unexpected breakdowns. Hydraulic shears are essential for cutting and shaping metal in various industrial applications, including aerospace, defense, and automotive. Proper winter maintenance not only helps extend the lifespan of your equipment but also ensures its reliability throughout the season.

Why Winter Maintenance Matters

Winter conditions can pose specific challenges to hydraulic machinery. Cold temperatures can affect hydraulic fluid viscosity, increase the risk of condensation, and potentially lead to equipment malfunctions. Implementing a proactive maintenance plan can mitigate these issues and ensure your hydraulic shears remain in peak condition.

Essential Winter Maintenance Tips

-

Check and Adjust Hydraulic Fluids: Cold temperatures can cause hydraulic fluids to thicken, affecting their flow and the overall performance of your shears. Ensure that the hydraulic fluid is suitable for winter conditions or consider switching to a winter-grade fluid if necessary. Regularly check fluid levels and top up as needed.

-

Inspect and Maintain Hoses and Connections: Cold weather can cause hoses to become brittle and prone to leaks. Inspect all hoses and connections for signs of wear and tear. Replace any damaged hoses and ensure all connections are secure to prevent leaks and potential system failures.

-

Clean and Lubricate Moving Parts: Ensure that all moving parts of your hydraulic shears are clean and well-lubricated. Winter can exacerbate issues with lubrication as cold temperatures can affect the consistency of lubricants. Use lubricants appropriate for lower temperatures and ensure that all moving parts are adequately coated.

-

Test the System: Before the cold weather fully sets in, run a test on your hydraulic shears to check for any performance issues. This includes testing the hydraulic pressure, operational functions, and ensuring that the system responds correctly to controls.

-

Protect Against Condensation: Cold temperatures can lead to condensation inside the machinery, which can cause rust and corrosion. Store your shears in a dry, well-ventilated area if possible. Consider using protective covers to shield the equipment from moisture and ensure a dry environment.

-

Schedule a Professional Inspection: Regular professional inspections can catch potential issues before they become major problems. Schedule a maintenance check with Independence Machinery to ensure your hydraulic shears are ready for winter.

Why Choose Independence Machinery

At Independence Machinery, we provide comprehensive diagnostics, repair, and maintenance services for large industrial machines, including hydraulic shears. Our expert team is equipped to handle all aspects of machinery service, ensuring your equipment remains reliable throughout the winter months.

Connect With Us

Prepare Your Hydraulic Shears for Winter

Explore our website, give us a call at (877) 8-INMACH, Independence Machinery offers expert diagnostics, repairs, and maintenance to help you stay ahead. Contact us to learn more about how we can support your machinery needs.