Ensure your ironworkers are running at peak efficiency with regular maintenance. Independence Machinery offers expert services to keep your equipment in top condition. Contact us today to schedule your maintenance and avoid unexpected downtime.

Comprehensive Guide to Ironworker Maintenance for Maximum Efficiency

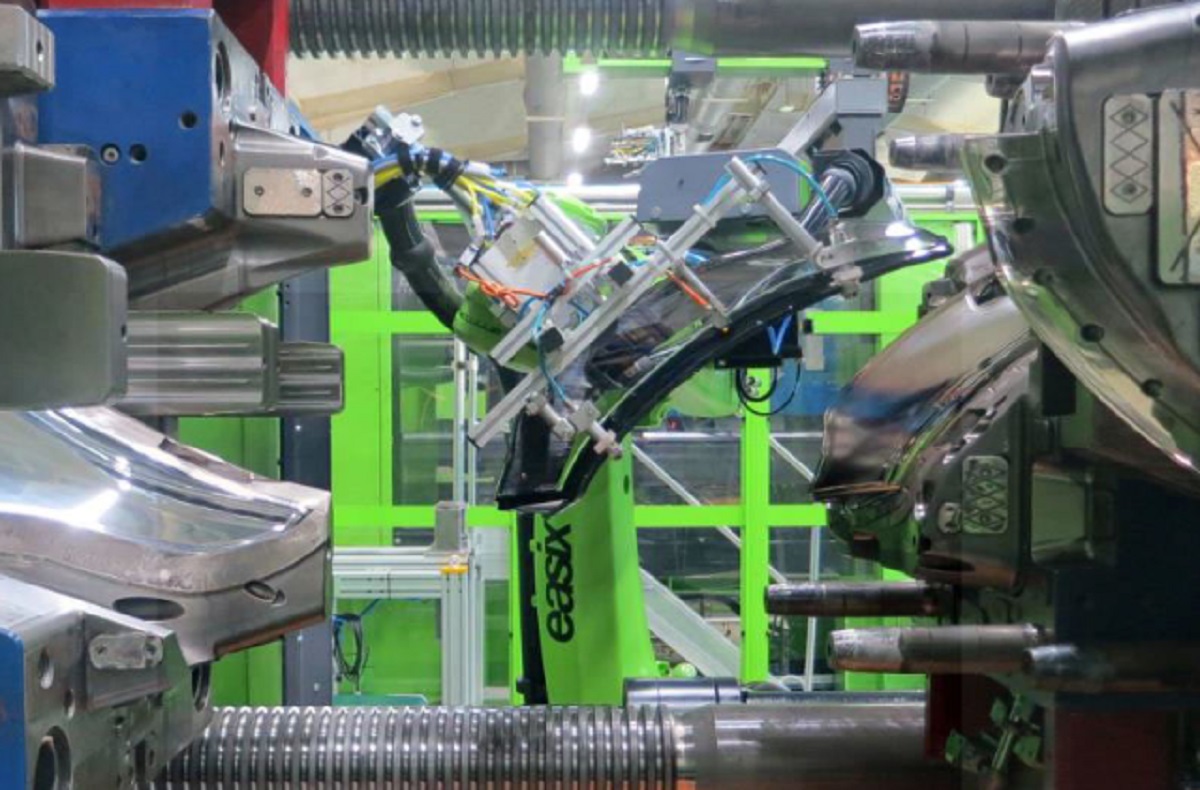

Ironworkers are essential tools in various industries, including aerospace, automotive, and industrial sectors. These robust machines are designed to handle heavy-duty tasks, from punching and shearing to bending and notching. To ensure that your ironworkers operate at peak efficiency, regular maintenance is crucial. At Independence Machinery, we provide expert diagnostics, repair, and maintenance services tailored to large industrial machinery, including ironworkers. This comprehensive guide will help you understand the key aspects of ironworker maintenance and how to keep your equipment in top condition.

Why Regular Maintenance is Essential

Ironworkers are subjected to rigorous use, which can lead to wear and tear over time. Regular maintenance is essential to:

Prevent Unexpected Downtime:

- Early Detection: Regular maintenance helps identify potential issues before they result in equipment failure, reducing the risk of unexpected downtime.

Extend Equipment Lifespan:

- Consistent Care: Proper maintenance practices help extend the operational life of your ironworkers, protecting your investment and reducing the need for costly replacements.

Enhance Operational Efficiency:

- Optimal Performance: Well-maintained ironworkers operate more efficiently, resulting in better performance and reduced energy consumption.

Ensure Safety and Compliance:

- Safety Standards: Regular checks and maintenance ensure that your equipment adheres to safety regulations and operates safely, minimizing the risk of accidents.

Key Maintenance Tasks for Ironworkers

To maintain your ironworkers in peak condition, follow these key maintenance tasks:

Routine Inspections:

- Visual Checks: Regularly inspect the machine for signs of wear, damage, or misalignment. Look for any loose bolts, frayed cables, or other visible issues.

- Functional Tests: Test the machine’s operations to ensure that all functions are working correctly, including punching, shearing, and bending mechanisms.

Lubrication:

- Proper Lubrication: Apply the appropriate lubricants to moving parts to reduce friction and prevent premature wear. Follow the manufacturer’s recommendations for lubrication intervals and types.

Cleaning:

- Remove Debris: Regularly clean the machine to remove dust, metal shavings, and other debris that can affect performance and cause wear. Keep the work area around the machine clean as well.

Adjustments and Calibration:

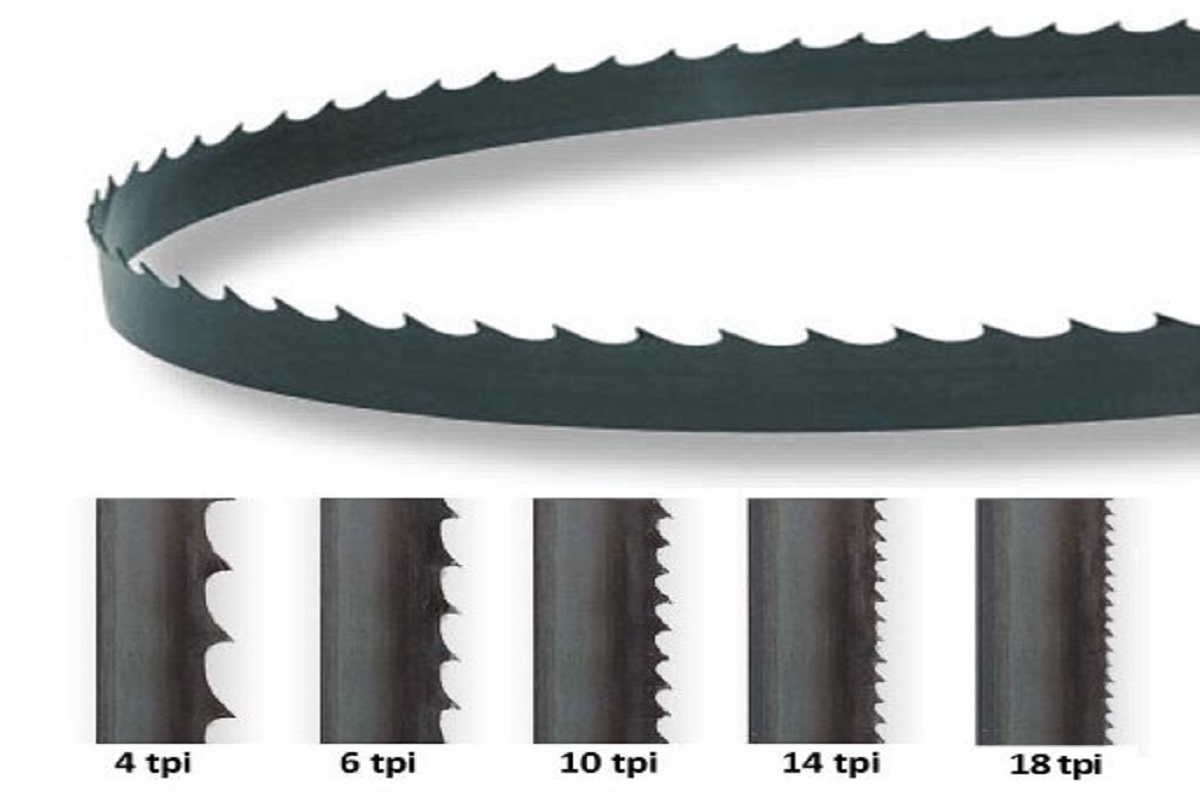

- Check Alignment: Ensure that all components, such as blades and punches, are properly aligned. Make necessary adjustments to maintain precision and accuracy.

- Calibration: Regularly calibrate the machine to ensure it meets the required specifications and maintains operational accuracy.

Inspect Hydraulic Systems:

- Fluid Levels: Check hydraulic fluid levels and top them up as needed. Inspect for any leaks or damage in the hydraulic system.

- Filter Replacement: Replace hydraulic filters as recommended to ensure clean and efficient operation.

Electrical System Checks:

- Wiring Inspection: Examine electrical wiring and connections for any signs of wear or damage. Ensure that all connections are secure and functioning correctly.

- Control Panel: Check the control panel for any error messages or malfunctions and address them promptly.

Training and Documentation:

- Operator Training: Ensure that operators are trained in proper maintenance procedures and understand how to identify potential issues.

- Record Keeping: Maintain detailed records of all maintenance activities, including inspections, repairs, and replacements.

Independence Machinery’s Support

At Independence Machinery, we offer comprehensive services for industrial machinery, including ironworkers. Our team of experts provides diagnostics, repair, and maintenance to ensure your equipment operates efficiently and safely. Whether you need routine maintenance or specialized repair services, we are here to help.

For more information on maintaining your ironworkers or to schedule a service, contact Independence Machinery today.

Connect With Us

Keep your ironworkers in top shape with expert maintenance from Independence Machinery. Contact us to schedule your service and ensure maximum efficiency.

Explore our website, give us a call at (877) 8-INMACH, Independence Machinery offers expert diagnostics, repairs, and maintenance to help you stay ahead. Contact us to learn more about how we can support your machinery needs.